Systems Modeling

Systems Design and Modeling Analysis Testing

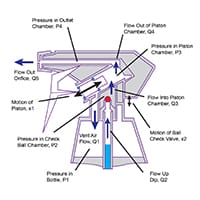

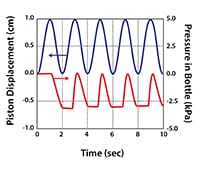

Stress Engineering Services regularly develops special-purpose time-domain dynamic simulation programs for our clients. These programs allow users to vary important parameters of systems such as dimensions, fluid properties, fluid volumes, and flow resistance coefficients. Output of these programs provides time-history traces of variables such as pressure and flow rate throughout the device being modeled. This technology has been applied to single-phase and two-phase modeling in a variety of industries. We have developed dynamic simulation programs for the following:

- Waterhammer feedback through heat exchangers

- Pressure-compensating valves

- Liquid-filling production lines

- Roof rupture in storage tanks

- Surge line analysis for butane compressors

- Drilling mud pumps

- Pulse-wave systems for down-hole drilling instruments

- Aerosol cans and spray-dispensing systems

- Down-hole motor driven core barrels

- Hydropercussive drill tools

- Deep-water drilling riser disconnect pressure transients

- Drill-string motion compensators

- Active motion compensation systems

- Regenerative hydraulic system for a fatigue test machine

- Faucets and mixing valves