Materials Selection & Characterization

Material Selection Assistance

At Stress Engineering Services, we focus on assisting clients with material selection processes to ensure that the most reliable and economic materials are chosen for a particular application. Our engineers use their diverse, in-depth experience and an assortment of testing and inspection methods to efficiently acquire the crucial data needed for practical material selection and qualification. We have decades of experience applying and, where necessary, developing situation-specific test methods to support metals, plastics, composites, and elastomer selection and qualification.

Whether the re-evaluation is driven by an aggressive environment, new technology, new supplier, or a change in regulatory policy; our knowledgeable team can help ensure that the design or end product achieves maximum performance and reliability at minimum cost. Our engineers can help select the best materials from the often overwhelming number of choices, and can determine exactly how those materials will perform in a given application.

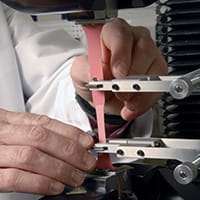

Laboratory-based material testing and characterization capabilities are the cornerstone of our well-renowned materials engineering services. Because we perform much of the testing and data acquisition in-house, we can provide a unique perspective on what specific material data and information is needed to ensure adequately robust designs, products, and components. We use a wide range of specialized tools to test and characterize the behavior of metals, plastics, elastomers, and composites.

The operating environment—temperature, corrosion, stress, and strain—can profoundly affect the life of a specific material. Making the right choice in materials can be hugely beneficial to the bottom line, but making the wrong choice can be costly and even dangerous. Our experienced team can provide the skills and technology to help avoid the potentially staggering costs of project delays, in-service failures, warranty claims or recalls.