Full-Scale Testing and in-Situ Monitoring of Pipelines

Pipeline Full-Scale Testing and Monitoring

Stress Engineering Services utilizes full-scale testing as both an assessment and predictive tool to support the integrity management programs of pipeline operators around the world. Our engineers and technicians are leading experts in using full-scale testing methods to evaluate all types of pipeline anomalies including dents, cracks, defects in seam welds and vintage girth welds, and wrinkles.

Full-scale testing of pipeline components and materials provides engineers with insights regarding the in-service behavior of their assets, including potential failure conditions. Our test programs not only highlight threats to pipeline integrity, but also give opportunities for evaluating remediation techniques and establishing reassessment intervals.

These testing techniques can be especially valuable when combined with numerical modeling and in-situ monitoring data. Validation of finite element modeling through full-scale testing enables future design efforts to more accurately simulate the service conditions experienced by the asset.

In addition to full-scale testing, in-situ monitoring is a valuable tool for assessing integrity of a pipeline. In-situ monitoring allows the external loading conditions such as ground movement that affect the pipe to be measured. These results can then be used to supplement numerical analysis and full-scale testing efforts or to make decisions about remediation. In-situ monitoring can be conducted on-site or set-up to remotely transmit data.

Burst Testing

Determines the ultimate pressure capacity of the sample by increasing internal pressure until failure occurs. The addition of strain gages located at areas of interest on the sample can provide valuable information on stress concentrations due to defects, crack opening due to internal pressure, or the level of reinforcement provided by threat mitigation techniques.

Pressure Cycle Fatigue Testing

Introduces cumulative damage to simulate future service. Can be used to determine fatigue life for a particular anomaly or combined with operational protocols such as future hydrotests. This is a useful technique for forecasting how a pipeline might perform at some future date.

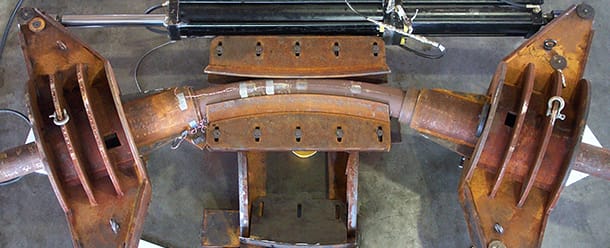

External Load Testing

Application of external loads to simulate a variety of scenarios such as thermal buckling, land movement, and pipe/soil interaction. These can include combined loading scenarios with bending, internal pressure and axial tension or compression.

Simulated Damage Creation

The process of simulating pipe damage in the test laboratory rather than using actual defective pipe materials from the field. Fabricated defects are often used during testing to represent corrosion, dents, wrinkles, or mechanical damage.