Mechanical Testing

Companies in the plastics and packaging industry are continually developing unique products that feature new performance-related functions. As a result, there is a need to measure the mechanical performance of such components and packaging to validate the uniqueness of the application.

Stress Engineering Services conducts a variety of tests on products and packaging for evaluating structural response under various manufacturing line, shipping, distribution, storage and handling loads. With our extensive experience in product/packaging design and analysis, we bring a unique physics-based insight and perspective to interpretation of test results and failure modes.

Types of Mechanical Testing We Offer:

Instrumented Drop Impact Testing

Both plastic components and packaging are subjected to drop/impact loading specifications in almost every segment of this industry. We routinely conduct fully instrumented drop impact testing on plastic products and packaging. Sizes range from very small devices all the way to 2500-gallon tanks used for containment of hazardous chemicals.

Fatigue Life Testing for Polymers

We have extensive experience in fatigue-life prediction and testing for the assessment of polymers. Utilizing our multi-station fatigue-life characterization systems, we can generate strain-life data for polymers under varying levels of mean (hydrostatic) stress. The resulting data is used in the fatigue calculations of plastic components.

Friction Testing

Measuring static and sliding coefficients of friction is a critical part of accurately calculating the functional attributes of plastic assemblies. With the use of our custom friction testing system we can characterize the static and sliding components of friction for a range of applications, including:

- Developing design calculations that employ FEA

- Ranking material combinations during the material selection process

- Defining minimum contact pressures required to maintain seal integrity

- Assessing effects of product (e.g., dry vs. wet state) on friction coefficient and subsequently mechanical function

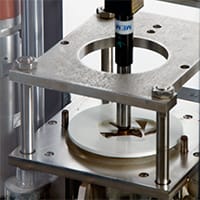

Custom Test Systems

We are frequently asked by leading companies to develop unique methods for testing products and materials. Our test systems are designed using sound mechanical principles, but with unique innovations to perform the desired measurement functions such as pressure, temperature, load/force, strain, and displacement. We also integrate the mechanical hardware with appropriate electronics and software required for data acquisition and control capabilities.

Our testing capabilities include: