TorqueStar Combined Load Testing

What is TorqueStar™?

What is TorqueStar™?

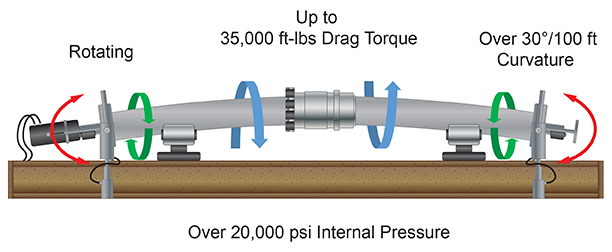

TorqueStar™ is a state of the art combined load testing system that simultaneously reproduces downhole loading conditions on tubulars and downhole equipment during all drilling and completion operations.

TorqueStar technology offers the ability to understand how the application of simultaneous torque with combined loading can ultimately affect the performance of equipment subjected to fatigue, overload, drift and sealability.

Now, for the first time, these tests can be performed under both static and dynamic combined loads in a fully instrumented laboratory environment for tubular connections or downhole tools. This negates the need for operating a drilling rig and paying its associated day rate to perform real world simulations – a cost-prohibitive proposition.

TorqueStar technology applies controlled torque, under combined axial bending, tension and pressure loads to simulate dynamic or static conditions for fatigue overload, drift, and sealability. Furthermore, a full simulation can be performed instead of having to move from one frame to another frame to simulate different separate loading conditions.

TorqueStar makes it possible to apply all of these loads simultaneously and provide a full comprehensive simulation of a drill string, downhole tool, bottom hole assembly (BHA) and/or a production casing/tubing during a full run as opposed to performing separate tests under the current standard ISO standard and API5C5 testing regime.

Ultimately, TorqueStar offers vastly improved ability for OEMs and designers to verify how their designs are functioning in today’s modern applications, thus providing confidence for the end user.

Specifications:

- Over 20,000 psi Internal Pressure

- Over 30°/100 ft. Bending While Rotating

- 35,000 ft.-lbs. Applied Torque during Fatigue Testing

- Up To 7 in. Pipe Diameters

Applications:

- Downhole Tool Testing

- Evaluating Casing Connection Performance in Multi-Fractured Horizontal Wells (API 5SF)

- Simulating Rotating Through a Dog Leg Curvature

- Combined Load Testing

Additional Information: