Reducing Cost on Current and Next Generation Products

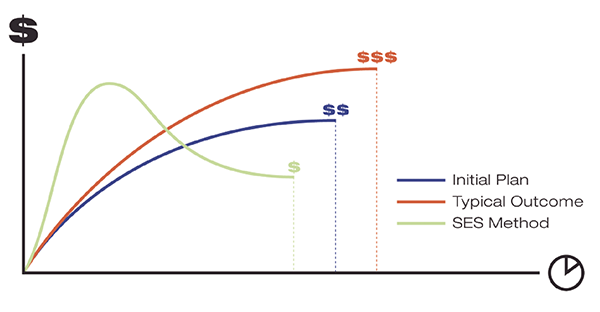

We apply the latest innovations in technology and materials science to optimize your product’s performance while simultaneously reducing costs. By using cost modeling, we help clients understand and take advantage of economies of scale as well as understand the right price to pay suppliers for materials and components. Also, we have techniques to quickly evaluate product performance relative to product requirements.

Improving the Bottom Line by Improving Quality

When quality problems arise, getting the right data is essential. We have a broad base of failure analysis, instrumentation, and testing expertise to get the data that drives the problem. We work alongside our clients to solve product quality problems before they have an adverse effect on business.