A Complete Approach to Ensure Piping System Integrity

Stress Engineering Services, Inc. offers an all-encompassing approach to piping system integrity. The program comprises all necessary elements: a review of the design, a walkdown, analyses, inspections, evaluations, and documentation. The end result is a complete program for piping that maximizes life and minimizes risk. This approach is suitable for all piping systems, including covered piping systems (CPS) such as main steam and hot reheat lines (systems with high consequences of failure).

Piping Failures Can Be Catastrophic

Piping systems are designed to ensure that pipe stresses and displacements operate within adequate safety margins. Piping failures can be expensive and can also place personnel at risk. Our engineering and materials experts regularly analyze piping failures stemming from:

- Improper Hanger Operation (excessive deflection, broken hangers, improperly operating hangers)

- Fatigue (vibration-based and creep-based fatigue)

- Creep and Creep Rupture

- Flow-assisted Corrosion (FAC)

A complete condition assessment of your piping can validate that the piping design is operating as expected, and also be used to establish the system’s condition in terms of life, fitness for service, required inspection intervals, and expected future performance.

Regulatory Requirements

ASME B31.1 (Chapter VII – Operation and Maintenance) requires a power piping fitness-for-service (FFS) program for CPS. This code has been adopted by over 35 US states and Canadian provinces. In 2016, the National Board Inspection Code Committee (NBIC) approved a ballot requiring piping systems to also be in compliance with B31.3.

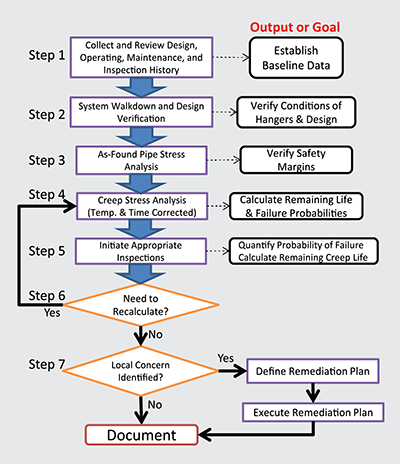

Step 1: Collect & Review Design, Operating, Maintenance, and Inspection History

Step 2: System Walkdown and Design Verification

Step 3: As-Found Pipe Stress Analysis

Step 4: Creep Stress Analysis

Step 5: Appropriate Inspections

Step 6: Assess Need to Recalculate Models

Step 7: Examine Local Concerns

Step 8: Documentation