From pipeline failure analysis to integrity management challenges, we know how to solve pipeline problems.

At Stress Engineering Services, we are experts in navigating the complexities of midstream operations, offering a full spectrum of solutions from failure analysis to mechanical integrity. Our proficiency encompasses high-pressure interstate gas pipelines, pipelines for oil and other hydrocarbons, and local distribution gas lines (LDC). In addition, we provide crucial crack management services, such as pressure cycle monitoring and lifetime anomaly calculations, ensuring operational safety and longevity.

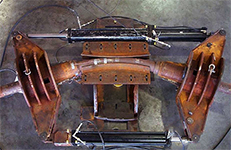

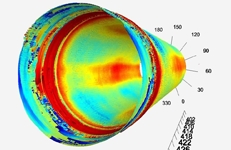

Our service offerings include ILI validation spools, strain capacity testing, pipeline repurposing, materials and corrosion testing, as well as hydrogen and CO2 testing. In addition, we provide testing and certification for integrity-related technologies like non-destructive examination (NDE) and in-line inspection (ILI).