Power Generation

Enhancing Power Station Operations with Proven Expertise

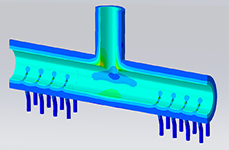

Stress Engineering Services combines years of experience in fossil and nuclear power stations with a broad range of engineering services to enhance plant operations. Utilizing advanced tools and industry insights, we address complex engineering challenges, enhancing efficiency, safety, and reliability while cutting costs and risks. Our approach includes sophisticated engineering analyses, field inspections, and fitness-for-service evaluations, particularly for high-temperature apparatus like boilers and HRSGs.

Our team’s direct experience in operational power stations enriches our capability to tackle issues including acoustic-emission testing of high-energy piping, API 579 assessments of fixed equipment, materials engineering, boiler-tube corrosion and water chemistry, welding and weld repair, creep testing and high-temperature assessment, and vibration issues related to flow.