An Innovative Asset Integrity Management Platform

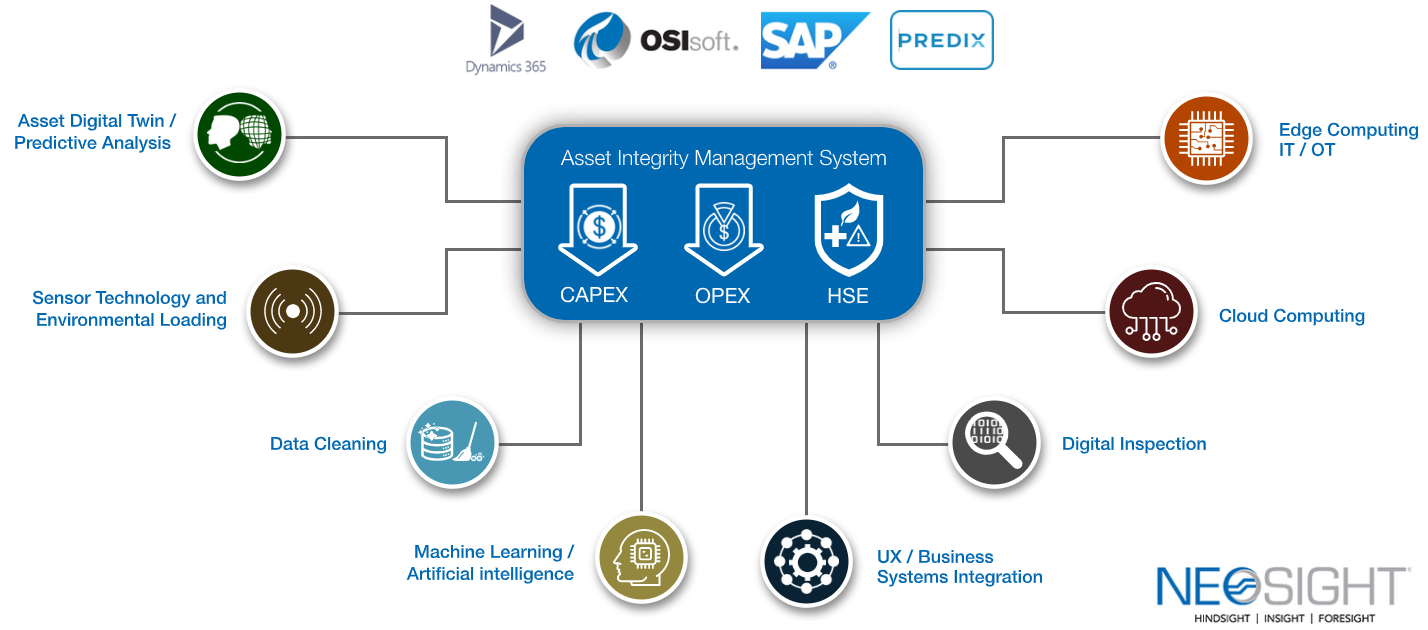

NeoSight® is an automated standalone integrity management system developed to enable operators to save costs, enhance operability and extend the life of their assets. This highly acclaimed innovation is the product of from Stress Engineering Services’ knowledge acquired and refined over decades of proven operations.

This advanced asset integrity management platform incorporates hindsight, insight and foresight into its evaluations, for a range of industries and applications. Leveraging and supplementing new or existing digitalization efforts, the NeoSight platform integrates directly with existing business systems in real-time or near real-time – reducing the time to action from days, or months, to minutes.

What is NeoSight?

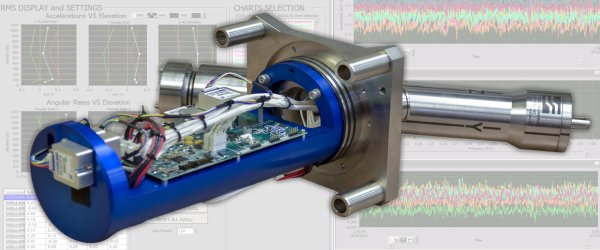

NeoSight is an automated standalone integrity management system, which enables data to be gathered from existing instrumentation to create digital models that provide a holistic representation of asset response. It creates a comprehensive model of your system, allowing you to simulate different operating scenarios, under various environmental conditions, in virtual space and accurately predict the outcomes. These integrated models create ‘virtual sensors’ to let you see the performance of critical components regardless of sensor coverage or availability, giving you a more comprehensive picture of your operations.

How it Works

The primary goal of every integrity management program is to protect the health and safety of people and prevent negative impacts to the environment. NeoSight fills the gap in asset integrity management by automating the link between data and physics-based models, enabling a continuous evaluation of the system of interest. NeoSight harnesses a deep understanding of the fundamental physics of the systems, their failure modes and other asset nuances, to provide a more complete analysis to support decision-making.

The Digital Twin Model

While other systems simply monitor measured responses or apply data analytic algorithms to diagnose problems, NeoSight enhances this information with physics-based models of the systems to provide a new level of hindsight, insight, and foresight. Our proprietary algorithms allow for quick processing of data that ensure analyses are updated in minutes rather than the hours competing technology requires. This advancement makes the predictive engine in NeoSight unique in its near real-time capability. Other technologies that claim to incorporate near-real time solutions are usually based on machine learning models trained using less reliable analysis leveraging design methodologies.

NeoSight is also well suited to provide life extension assessments and can simulate:

- Floating Production Storage and Offloading (FPSO)

- Single Point Anchor Reservoir (SPAR)

- Semi-Submersibles | Tension Leg Platforms

- Riser Systems

- Blow Out Prevents (BOP)

- Operator’s Wellhead/Casing Assembly