Winner of the 2017 OTC Spotlight on New Technology® Award

and the 2017 Oil & Gas Engineering Product of the Year Silver Award

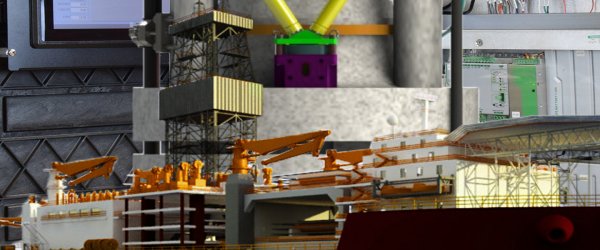

In offshore oil & gas development, vessels and platforms are continuously exposed to severe environmental conditions including underwater currents. Marine risers, which act as a conduit for drilling, completion, workover, and intervention operations are also susceptible to damage. Wellheads and conductor casing, whose structural integrity is paramount for safe drilling and operation merit particular concern as BOP stacks become larger and more massive.

These systems undergo constant wave loading. Furthermore, underwater currents can excite forced oscillations, known as Vortex Induced Vibration (VIV). Vibrations sustained over a period of time can cause excessive fatigue damage to welds and couplings in the riser string.

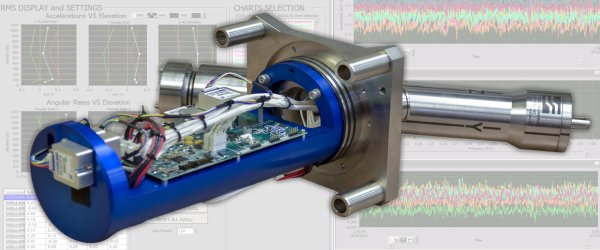

At Stress Engineering Services, we have developed the Realtime Fatigue Monitoring System (RFMS®) to provide field measurements of stress and fatigue on drilling risers, wellheads and other subsea systems in near real time (online versions) or in a short time after data is retrieved (offline versions). The objective of the RFMS is to monitor riser fatigue damage caused by VIV and wave loading. The RFMS utilizes our advanced vibration monitoring instrumentation and data acquisition capabilities, along with precise analytical modeling information, to determine real-time stress and fatigue damage located anywhere in the riser system. Real-time stress and fatigue estimates for the wellhead and conductor casing can easily be included by attaching vibration sensors to the BOP/LMRP stack, wellhead, or conductor.

Realtime Fatigue Monitoring System Advances Integrity Management

The RFMS significantly advances riser integrity management and as a result, drilling engineers are empowered with a tool that provides real-time data on the integrity of the drilling riser, enabling informed decisions to be made in adverse environmental conditions.

- Support safe and productive operation

- Monitor fatigue damage in critical areas, such as the wellhead, conductor casing and riser

- Achieve an effective joint rotation, inspection and fatigue tracking program

- Minimize downtime

- Validate and improve mathematical models (reduce conservatism)