Laser Pipe Inspection

For years, laser scanning has been used extensively by the military, aerospace industry and NASA. This highly developed technology is also considered the new frontier in data acquisition and analysis for the oilfield.

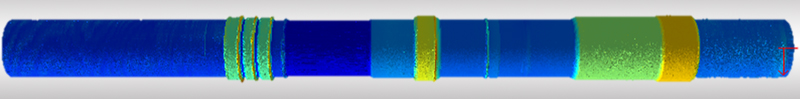

Our laser-based pipe inspection service is part of our non-destructive testing, asset condition-based maintenance and monitoring, predictive data analytics, and IoT ecosystem. The laser-based pipe inspection service helps to manage and assess baseline and degradation in tubulars.

Utilizing the high-performance BEMIS™ (Bore Erosion Measurement and Inspection System) tool, we are capable of rapidly, accurately, and quantitatively mapping the internal surface of 2″ – 21″ diameter pipes. BEMIS™ is a product developed by Laser Techniques Company LLC, and is the only system that accurately measures and maps the ID of pipe/tubing. This advanced level of inspection is designed to benefit those with a stake in identifying and managing risks and the deterioration of their tubular assets.

Our laser-based pipe inspection generates high-resolution data points that can be used to:

- Determine material loss due to pitting and/or mechanical wear.

- Characterize features to deduce if they were caused by wireline, drill pipe, corrosion, or a manufacturing flaw.

- Perform a detailed analysis of the entire tube, including the pin end and ID weld dimensions, including locations where UT cannot provide adequate inspection.

Applications:

- Highly accurate pipe and drill pipe ID and volume measurements

- Inspection of Drilling and Production Riser for return to service

- High Pressure Hose “CoFlex” and Iron Inspection for erosion

- Investigative “CSI” work for a failed work string or tubing

- Corrosive environment determination, i.e. corrosion, erosion and pitting, etc.

- Production Tubing Inspection including coupling

At Stress Engineering Services, we are dedicated to providing the best technology available for the inspection and analysis of oilfield equipment, forever conscious of the need to preserve life, respect the environment, and deliver the most reliable and complete information necessary for making critical decisions.

Additional Information: