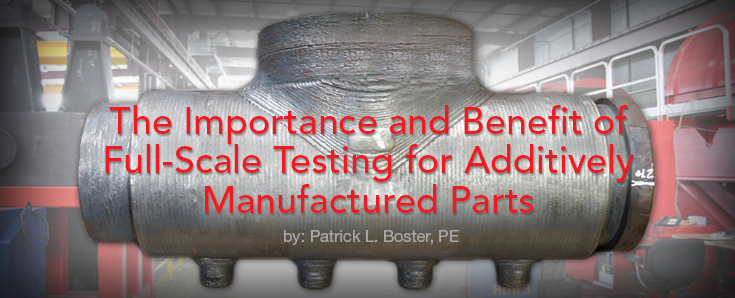

Accelerating Routine Maintenance Timelines with WAAM Parts

Discover how a crucial partnership between a domestic oil refinery, Lincoln Electric, and Stress Engineering Services dramatically shortened equipment maintenance timelines. Leveraging Lincoln Electric’s Wire Arc Additive Manufacturing (WAAM) technology for component production and our comprehensive additive testing and validation, this collaboration reduced anticipated downtime from four months to just four weeks. Gain insights into our role in full-scale product validation and the strategic navigation of complex regulatory standards to ensure the rapid deployment of additively manufactured parts.