Material Condition and Remaining Life Assessment

At Stress Engineering Services, we perform material condition assessments on vessels and high temperature plants by extracting small material samples commonly referred to as “scoop” samples. These samples can be taken at various depths so that minimum wall is not violated, and weld repairs are not required.

Aging equipment, the buying and selling of power plants and refineries, along with more aggressive service makes it more important than ever to understand remaining life in support of run/repair/replace decisions. The first step in assessing the condition of material in question is the completion of a thorough metallurgical evaluation. Safely extracting small “scoop” samples provides a vehicle to do this evaluation without requiring a section of piping or vessel to be cut out, forcing the operator to make significant repairs.

Small Material Sample (SMS) Methodology

Recognizing the need for data on the condition of material that is conclusive and minimally invasive, we have improved an existing method for extracting a Small Material Sample (SMS).

Cutting Scoop Samples

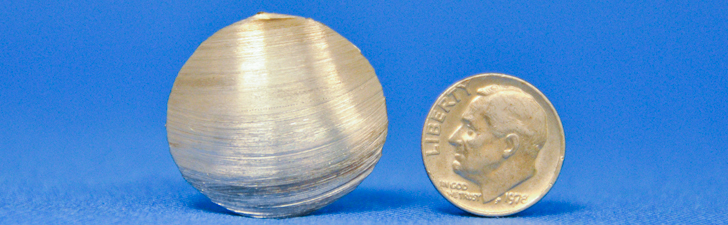

The pneumatically powered scoop sample cutter is secured to a vessel or pipe magnetically, or with fast setting epoxy. A shallow, spherical 1.25-inch diameter disc is sawed out. The cutter is adjusted to make sure the combined thickness of the sample and saw kerf are above ASME minimum wall requirements, so post extraction weld repairs are not necessary. For piping, samples can be removed from pipes as small as 10” and as large as 30”.

Absolute Confirmation of Component Metallurgy

Once extracted, the material samples can be used to create metallurgical specimens for detailed evaluation of possible aging mechanisms such as creep, HTHA, and various types of cracking. This approach eliminates ambiguity regarding the need for remediation, if necessary.

The Future of Small Material Sampling

We are in the process of developing and validating a range of tests using sub-size specimens cut from small scoop samples in support of remaining life assessments. These include:

- Tensile Creep Testing

- Miniature Fracture Toughness Tests