At Stress Engineering Services, our focus is on developing test procedures that will accurately assess the behavior of a product or packaging, determine possible modifications, and provide highly efficient solutions. We cater to a broad range of industries including consumer and medical products, packaging, pharmaceutical, and electronics to name a few. In addition, our staff is experienced with a variety of materials including plastics, metals, composites, glass, and elastomers.

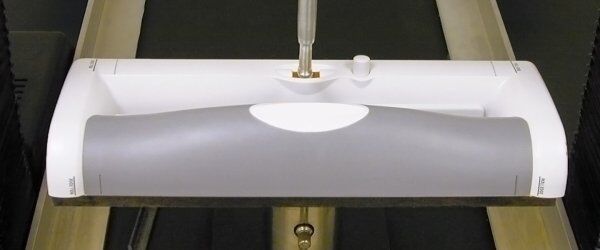

We specialize in measuring a variety of factors that can significantly affect the functionality of products and packaging, including rapid loading rates, varying temperatures, extreme forces, displacement, deflection, acceleration, vibration, cyclic events, and others.

Performance, reliability, and safety are critical to the success of a product or package. We offer a variety of custom services aimed at evaluating these factors, including precision testing for low force and sub-micron displacement, noise and vibration. Our engineers can test unique performance criteria on conventional products or standard criteria on unusual designs, including life cycle, life simulation, extreme environment, and extreme usage.

We provide third party testing services in accordance with API, ASME, ANSI, ASTM and others. Where agency approvals are needed, we can manage outsourcing of those tasks and provide the technical interface.