What is NeoSight?

Advanced integrity management through automated data analysis and predictive modeling

Assets operating in taxing environments present tremendous challenges in maintaining safety, integrity and operability: challenges that industry meets with perseverance and innovation. Many organizations are responding to market pressures by increasing operating efficiency and better monitoring and maintaining their assets.

Insight is traditionally gained by leveraging data to make decisions. However, as data systems grow increasingly advanced, raw data has become more prolific. This creates new challenges in obtaining real insights from the vast amount of data being generated by sensors, which themselves are being exposed to the same challenging environment as the mechanical and human investments they are installed to protect. Crucial performance and system health indicators can remain obscured for months or years at a time in an overload of data, leaving the assets vulnerable to the harsh financial ramifications of unplanned downtime, unrealized capacity or unforeseen reliability issues.

Inadequate use of data is a hidden and serious cost for organizations, representing up to 20% of operational budgets and the challenges of managing and using the growing amounts of data for analytics are only increasing. It is no surprise then, that companies are implementing ‘data smart’ information management and predictive analytics systems to become more profitable in their operations.

What is NeoSight?

Hindsight | Insight | Foresight

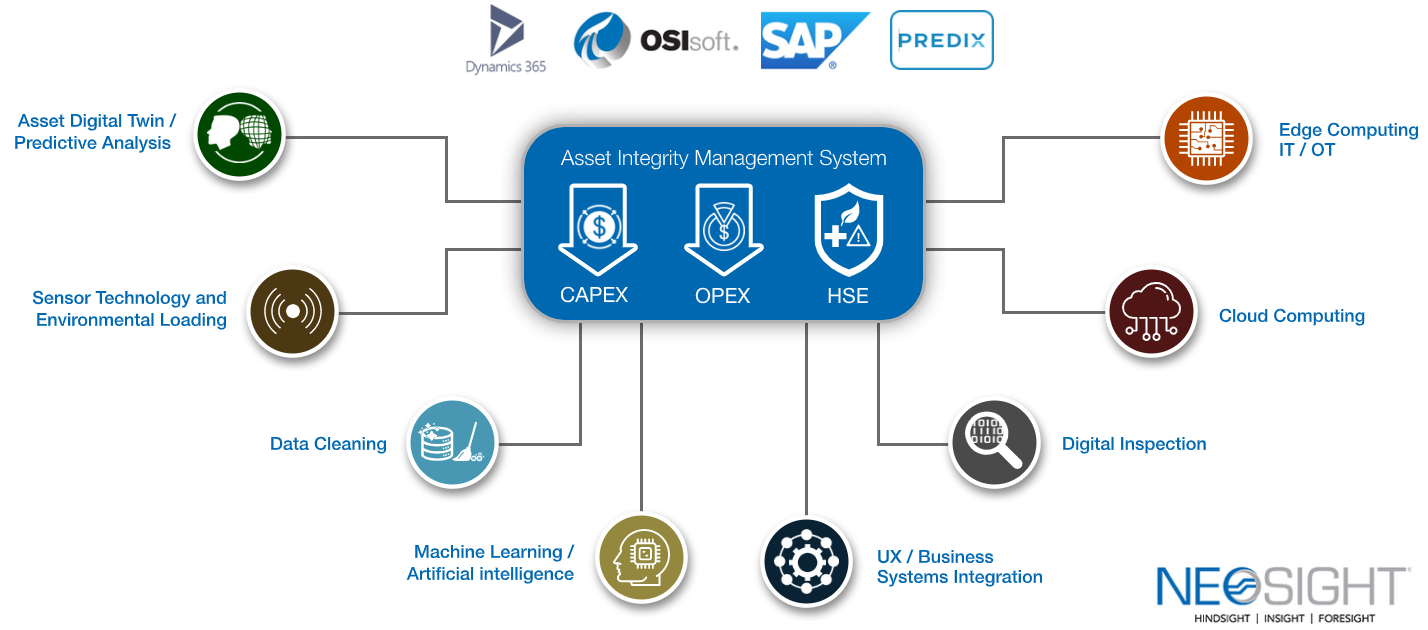

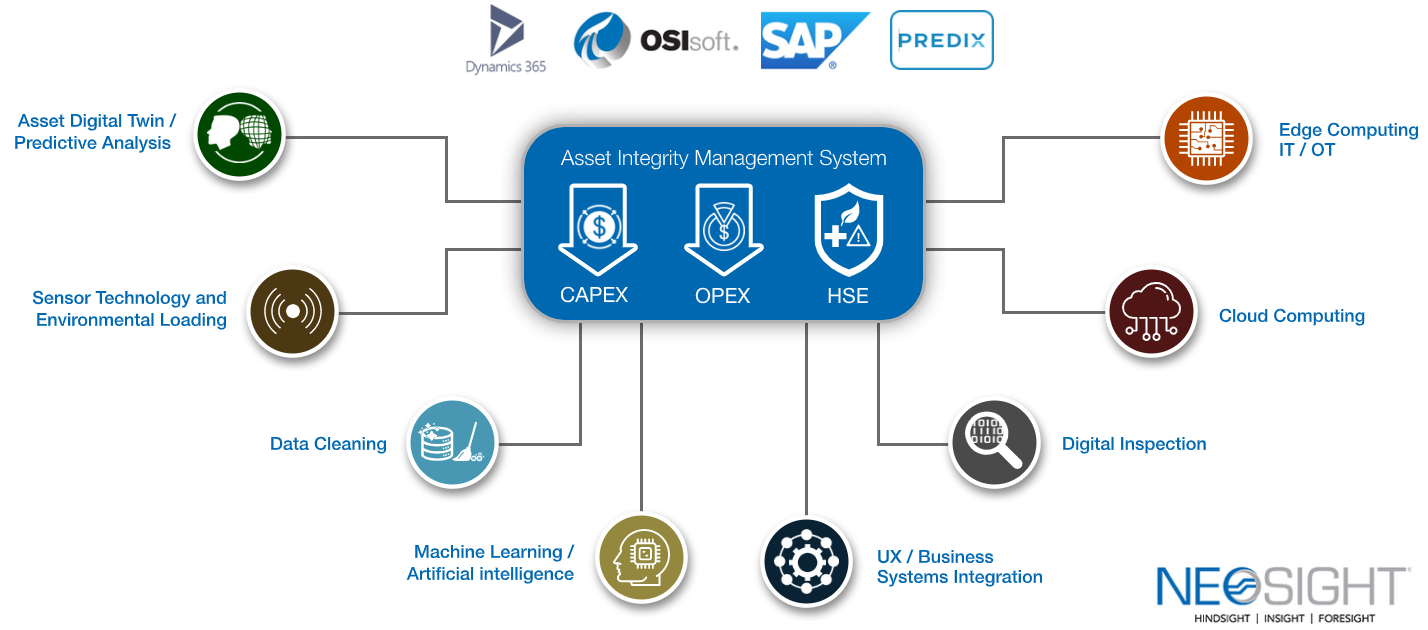

NeoSight® is an automated standalone integrity management system, which enables data to be gathered from existing instrumentation to create digital models that provide a holistic representation of asset response.

The NeoSight platform represents the culmination of our experience as the leader in advanced simulation technologies, at the forefront of innovation. The primary goal of the platform is to provide hindsight, insight and foresight into the performance and integrity of an asset, regardless of industry or application. NeoSight is a platform designed to leverage and supplement new or existing digitalization efforts. For applications where no architecture currently exists, NeoSight can be used as a standalone product. The NeoSight platform integrates directly with the existing line of business systems in a real-time or near real-time fashion.

Physics-based Digital Twin Models

The principal advantage of NeoSight is that at the heart of each tool developed on the NeoSight platform is a physics-based digital twin model that accurately simulates the asset response. The digital twin concept represents the joining of data with a computer model of an asset, whether a component, process or system. The condition and performance of the asset can then be assessed in virtual space using the model capabilities. Digital twin models allow for the integration of inspection, analysis and measured data providing important, previously unavailable insights into asset behavior. The digital twin technology can leverage big-data analytics, but they are not dependent on big-data analytics, which are typically best suited for applications where data are available for hundreds (or thousands) of similar components.

Maximizing Asset Efficiency

NeoSight represents the application of our unsurpassed expertise to a challenge that companies across industries are facing: the need to leverage data in maximizing asset efficiency through automated, streamlined processes. Through a combination of advanced technology and a fundamental understanding of economics, NeoSight can help you get more out of your assets and optimize profits like never before.

If you would like more information on Stress Engineering Services, please call us at 281.955.2900, or complete the following form and one of our representatives contact you shortly. For a complete listing of contact information, visit our Locations page.

"*" indicates required fields