SES IoT Applications Laboratory™

Although the so-called “Internet of Things” (IoT) and “Industrial Internet of Things” (IIoT) are frequently associated with 5G cellular technology (which is still some distance in the future), the race to realize some of the promise of ubiquitous internet connectivity, analytics, and feedback has begun. One of the most prevalent and successful applications thus far is the category of personal wearable devices (an IoT application) which includes smartwatches and fitness trackers. It is estimated that 1 in 6 internet users currently own one of these devices.

For decades, Stress Engineering Services (SES) has been recognized by clients around the world as a premier supplier and developer of sensors and instrumentation systems along with tools to analyze large data sets to address a broad range of technical problems. This history has become the foundation of our focus on IoT application development. Responding to the needs of clients, SES has begun to focus significant effort on instrumentation planning, sensor development, embedded analytics, and data management for product manufacturers and industrial clients and manufacturers. The range of application to date is very broad and includes archery products, healthcare-related initiatives, pharmaceuticals products, and safety-related applications aimed at reducing workplace injuries (Figure 1).

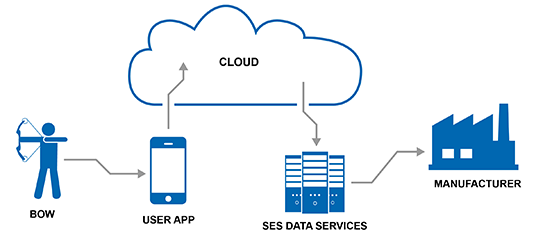

Figure 1: A schematic representation of the current path of data to users and manufacturers for the SES IoT Applications Laboratory™ archery projects currently underway.

One exciting application under development by Stress Outdoor® (a division of SES) is ‘Intelligent Bow” technology for application in the crossbow and compound bow archery market (Figure 2). Intelligent Bow provides many advantages to both the user and the manufacturer.

Figure 2: Cam sensor being developed for Stress Outdoor® Intelligent Bow technology.

Data from the Intelligent Bow sensor are sent to a mobile APP that provides an enhanced experience to the user by documenting the performance of the bow/arrow combination for each shot, checking for potential maintenance and safety-related issues on the bow, and logging the history of each bow shot (Figure 3).

- More accurate analytical models that can better predict fatigue-critical locations in the system

- Development of risk-based inspection plans

- Direct and/or indirect calculation of fatigue damage

Figure 3: Example of Intelligent Bow User APP.

SES’s Path to the IIoT

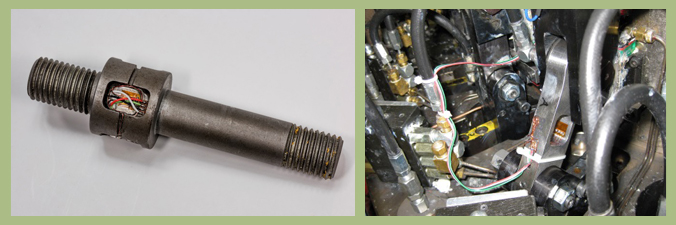

Because “real-world” problem solving requires real-world data, SES has become an expert in creating robust instrumentation to generate data to analyze and solve clients’ problems. Creating a sensor from a machine element is one common approach used by SES (Figure 4).

Figure 4: Examples of machine elements modified, instrumented and calibrated to provide operating performance data.

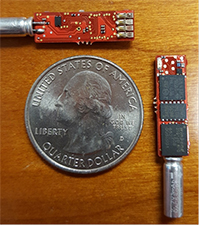

Because available space and power are normally limited, product instrumentation applications typically require the development of custom electronics to “ride along”, or be integrated into, the product during its life to gather data. In most cases, the chip (Figure 5) needs to be sufficiently unobtrusive to avoid overt detection by the user. After product data are collected, they can be processed locally, communicated to other products in close proximity, or transmitted where needed either wireless or via a tether.

Figure 5: Example of a small sensor developed for a product tracking applications.

** This article appears in the 2017 issue of Stress Talk **

Clint A. Haynes – VP/Managing Principal, Cincinnati Office

Joe K. Bullard – Analyst, Cincinnati Office

Clint Haynes has spent his career conceiving and supporting product development efforts in the consumer products, medical device, industrial products and machinery market spaces. His recent efforts leading Stress IOT Applications Laboratory™ integrates a broad range of the technologies common to these markets.

Joe Bullard’s specialty is in the complete design of embedded control, PLC based control, and motion control systems as well as, analog and digital systems design, failure analysis, electronic simulation and investigation.

Leave a Comment

You must Register or Login to post a comment.