Additively Manufactured Components Testing: Our Comprehensive Process for Full-Scale Validation

By: Patrick L. Boster, PE

At Stress Engineering Services, we recognize that transitioning from concept to solution in additively manufactured parts encompasses numerous complex challenges. This article describes our full-scale testing process, specifically engineered to overcome these challenges, ensuring that each component we assess is not only functional but also ideally suited for the stringent demands of its intended applications.

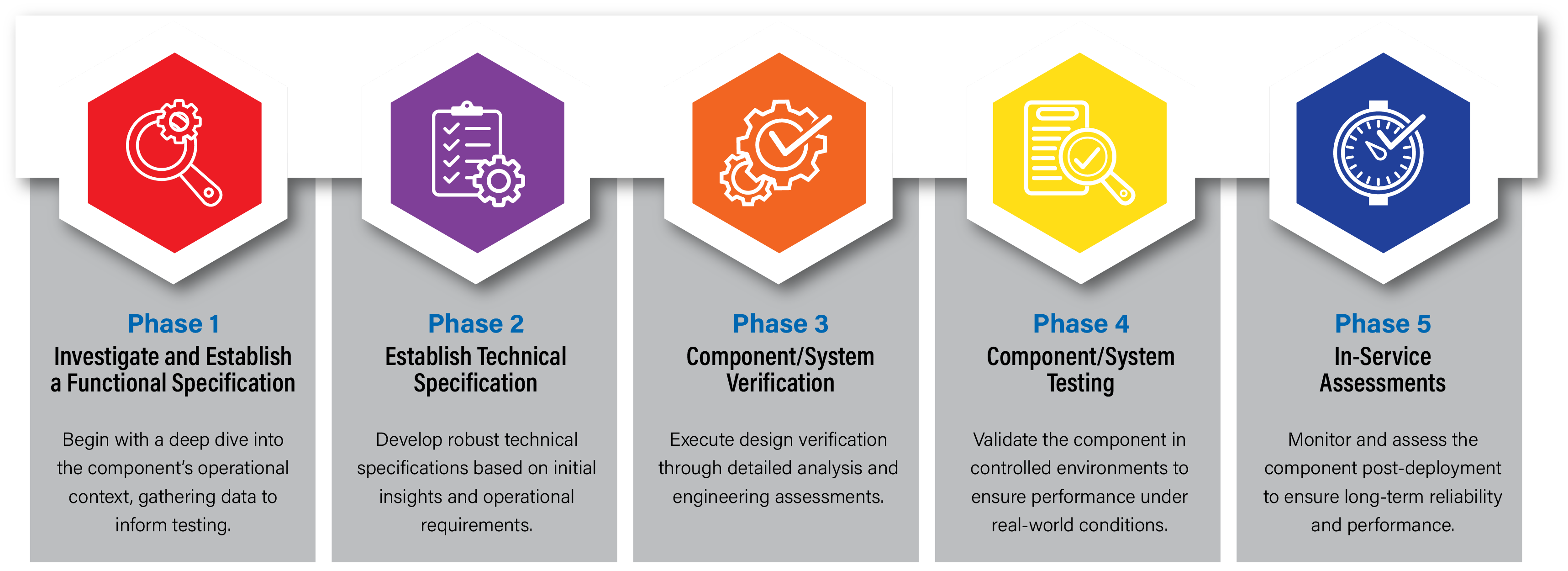

Our Protocol for Additively Manufactured Component Qualification

Each phase of our qualification process for additively manufactured components is underpinned by precision. We employ a multi-disciplinary engineering approach that meticulously addresses all critical variables to ensure that every component achieves, if not surpasses, industry standards.

Phase 1: Investigate and Establish a Functional Specification

The journey begins with a comprehensive evaluation of the application, transitioning seamlessly into a precisely engineered specification. Our team collaborates closely with end-users, conducting application reviews and in-depth interviews with engineers and technicians. This extensive investigation captures the operational environment and translates the collected data into detailed technical documents.

Our objective is to create a certifiable process that lays the groundwork for developing a technical specification. This ensures that the additive manufacturing provider accurately delivers the product on the first attempt, setting a solid foundation for informed and effective testing.

Phase 2: Generate a Technical Specification

Building on the insights gathered, we craft a detailed technical specification that aligns perfectly with the operational and functional requirements of the part. Our specifications, informed by vast practical experience and regulatory insights, enable us to design precise testing and manufacturing strategies. These specifications encompass manufacturing and inspection test plans to address the functional application and validate the engineering design model. They also ensure compliance with applicable codes and standards and assist in the necessary engineering requirements and verification testing for each unique application.

Phase 3: Component and System Verification

Stress Engineering Services performs meticulous design verification through the development and review of comprehensive calculation packages and Finite Element Analysis (FEA) models. Our team can function both as an integral virtual engineering team for clients or as an independent third-party verification entity. This phase is crucial to confirm that the design will withstand the expected operational conditions. We support these designs with thorough analyses and qualifications to ensure the component’s integrity remains unquestioned.

Phase 4: Component and System Validation and Compliance

Validation moves beyond theoretical analysis to practical, real-world testing scenarios. We employ various engineering verification methods in our controlled laboratory setting to capture real-time data that confirms material performance. Techniques such as Digital Image Correlation (DIC) validate or calibrate the FEA model, ensuring its accuracy and suitability. Additionally, Acoustic Emission (AE) technology is utilized to monitor material subsurface volumetric changes under stress, proving invaluable during extensive fatigue testing.

Our active roles in key industry committees, including the American Society of Mechanical Engineers (ASME), American Petroleum Institute (API), Association for Materials Protection and Performance (AMPP), the American Welding Society (AWS), and other safety authorities, allow our engineers to apply their deep understanding of regulatory nuances to our testing protocols, ensuring compliance and certifying each technology for operational deployment.

Phase 5: In-Service Assessments

Our engagement doesn’t end after the initial verification and validation phases. We continue with in-service assessments that monitor real-world conditions affecting the component’s design and material performance. Our pioneering work, such as the monitoring of the Shell Bullwinkle Jacket, involves condition-based monitoring with integrated sensors to assess operational behavior comprehensively.

This real-time feedback provides health reports and enables clients to consider life extensions and potential capital expenditure savings. Our Measurement and Control group continually develops innovative methods for performance evaluation, now presented through a comprehensive, intuitive dashboard.

From Testing to Trust

From the initial investigation to extended in-service assessments, Stress Engineering Services delivers unmatched scrutiny, ensuring that every component we test meets the demands of its final installation. After testing, we issue a Certificate of Conformance (CoC), affirming that the component satisfies all specified engineering criteria and is prepared for field installation. We also offer health monitoring systems that enhance your risk management strategies.

Stress Engineering Services transcends the role of a testing partner; we are your collaborators in navigating the complexities of additive manufacturing, transforming your engineering concepts into certified, market-ready solutions. Contact us today to explore how we can support your additively manufactured component applications.

Patrick L. Boster, PE – Senior Vice President, Houston Office

Patrick is an accomplished leader, engineer, and expert in Additive Manufacturing, Product Qualifications and Welding Engineering. His professional experience and background includes over 40 years of materials and welding engineering and manufacturing support. This includes project management, product development, design review, nondestructive evaluation, and validation of manufacturing technology methods to successfully deliver equipment for even the most challenging offshore applications. He has also worked on prototype validation testing, equipment delivery and condition-based monitoring of offshore installations. Patrick has a Bachelor of Science Degree in Welding Engineering from The Ohio State University and is a registered professional engineer in the State of Texas.

Leave a Comment

You must Register or Login to post a comment.