Enhancing Lithium Battery Safety in Transportation

A conversation with Carlos F. Lopez, P.E. of Stress Engineering Services…

In the rapidly evolving landscape of energy storage, lithium-ion batteries play a pivotal role. However, the safety of these batteries during transportation remains a significant concern due to the risk of thermal runaway—a dangerous condition where a battery overheats and potentially catches fire or explodes. We recently sat down and spoke with Carlos Lopez, a Senior Associate and technical lead for Battery Testing Services at Stress Engineering Services (SES), who shared some valuable insights into the mechanisms of thermal runaway and the innovative methods SES employs to enhance battery safety.

Understanding Thermal Runaway

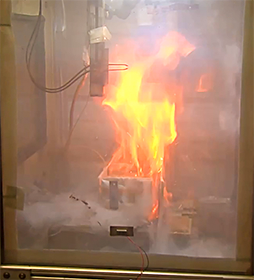

Carlos describes thermal runaway as a self-perpetuating, uncontrollable increase in temperature within a battery cell or pack, often leading to catastrophic failure. This condition can occur under off-nominal electrical, mechanical, or thermal conditions, triggering a chain reaction of chemical processes that generate excessive heat. As the temperature rises, battery materials may decompose, releasing toxic and flammable gases which can lead to smoke, fire, or explosions. The risk is particularly acute in settings like aircraft cargo holds where a single failing cell can jeopardize the safety of the entire aircraft.

SAE G27 Standards and Research

The SAE G27 Lithium Battery Packaging committee focuses on developing minimum performance standards for the safe shipment of lithium batteries. According to Carlos, the tests mandated by these standards assess the performance of battery packaging designs in simulated cargo hold environments. These tests are crucial for determining if packaging can effectively contain and mitigate a thermal runaway incident without leading to a fire.

Innovative Testing Methods at SES

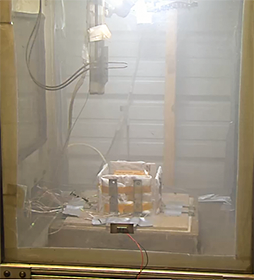

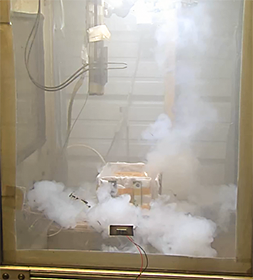

SES utilizes a specialized G27 chamber to study thermal runaway propagation under conditions mimicking an aircraft cargo hold. This chamber allows for the simulation of cell-level defects through thermal abuse, using heating tape to initiate thermal runaway. Supplementary spark ignitors provide an additional layer of realism by simulating potential ignition sources to determine the flammability of the battery off-gases. SES’s comprehensive approach also includes monitoring temperature at multiple points, cell voltages, chamber pressure, and capturing video data, which are critical for analyzing the behavior of batteries under duress.

For ground or vessel transportation, SES tests packaging that adheres to various regulatory standards. These tests ensure that the packaging can withstand and contain thermal runaway conditions, significantly enhancing safety. Tested packaging solutions range from simple cardboard boxes to robust steel drums, each designed to meet stringent safety specifications.

Key Findings and Recommendations

Carlos highlighted several surprising outcomes from their tests, including energetic combustion events that challenge preconceptions about the safety of certain battery configurations and packaging. Notably, tests have shown that combustion of off-gases can occur at lower states of charge than previously anticipated. These findings have led SES, in collaboration with UL Electrochemical Safety Research Institute, to propose changes to the G27 testing methodology, underscoring the lack of a one-size-fits-all solution to battery safety.

Impact on Lithium-Based Cell Transportation Safety

Carlos is optimistic about the impact of SES’s research on enhancing the safety of lithium battery transportation. By focusing on the performance of battery packaging, SES aims to mitigate the risks associated with transporting lithium batteries, potentially reducing the incidence of catastrophic failures in transit. This research is particularly relevant today, given the high production volumes of lithium batteries and the inevitability of manufacturing defects.

Stress Engineering Services’ commitment to advancing battery testing and safety standards is evident in their rigorous approach to understanding and mitigating the risks associated with battery thermal runaway. Their work not only contributes to safer transportation solutions but also fosters a deeper understanding of battery behavior under extreme conditions, paving the way for more resilient energy storage solutions.

The ongoing efforts by teams like those at SES play a critical role in shaping the future of battery safety in transportation, ensuring that as the demand for energy storage grows, so too does our ability to manage the risks associated with these powerful technologies.

Carlos F. Lopez, P.E. – Senior Associate, Houston Office

Carlos has a broad skill set encompassing fluid dynamics analysis, heat transfer analysis, electrochemistry, structural analysis, and testing with a focus on applications in the energy industry. He has extensive experience in battery testing and simulation in addition to experience in computational fluid dynamics and thermal analysis in a variety of applications.

Leave a Comment

You must Register or Login to post a comment.