Flow Corrosion Effects Using Jet Impingement Corrosion Testing

Jet impingement testing is effectively employed to study the effects of flow on the corrosion of materials, and the effects of flow on corrosion inhibitor performance. Stress Engineering Services has improved and refined this technique to allow both in-depth scientific investigations and routine testing.

The wall shear stress on the test sample is the correlation factor used to relate the corrosion results to field operating systems. Wall shear stress measures the interaction of a flowing fluid with a solid surface. It can be related to any flow geometry, because it is a basic fluid/wall interaction phenomena and not a function of the specific flow geometry.

Jet impingement experiments using technology developed by have well defined wall shear stress acting on the test specimen, which is effectively correlated to any flow geometry. The wall shear stress in an operating system is identical in its effect on corrosion to the wall shear stress in the jet impingement experiment. Therefore, the corrosion rate measured in the jet impingement experiment is directly related to the expected corrosion rate in the operation.

Features of this jet impingement testing system used by Stress Engineering Services include:

- Correlation of test results to actual process flow conditions and flow regime.

- Accurate slug flow simulation and correlation.

- Instantaneous corrosion measurements in multiphase environments; water with entrained oil and gas, gas with entrained water and low water cut oil.

- Recirculating and once-through flow tests.

- Corrosion inhibitor evaluation at varying shear stress, and for shear stress transients.

- Accurate determination of critical corrosion inhibitor concentration.

- Accurate determination of corrosion inhibitor persistency (once-through).

- Determination of acidizing and spent acid flow-back flow effects.

- Accurate evaluation of batch and batch/continuous corrosion inhibition.

Test Apparatus Design

The jet impingement test apparatus design is simpler and easier to operate than previous designs, and provides vastly superior temperature control, without the temperature fluctuations that occur with immersion heaters. The wall shear stress range obtainable with the present system is from 20 to 1000 Pa.

Modification of the basic recirculating liquid apparatus allows flow through operation and/or operation with liquid containing entrained gas, simulating of multiphase production and gas lift systems. The jet impingement test system is combined with corrosion probe technology allowing linear polarization corrosion measurements in high resistivity systems. This permits the application of jet impingement techniques to gas flow with entrained liquid (simulating annular flow conditions in gas production systems), and to oil flow with entrained water phase (simulating of low water cut multiphase production).

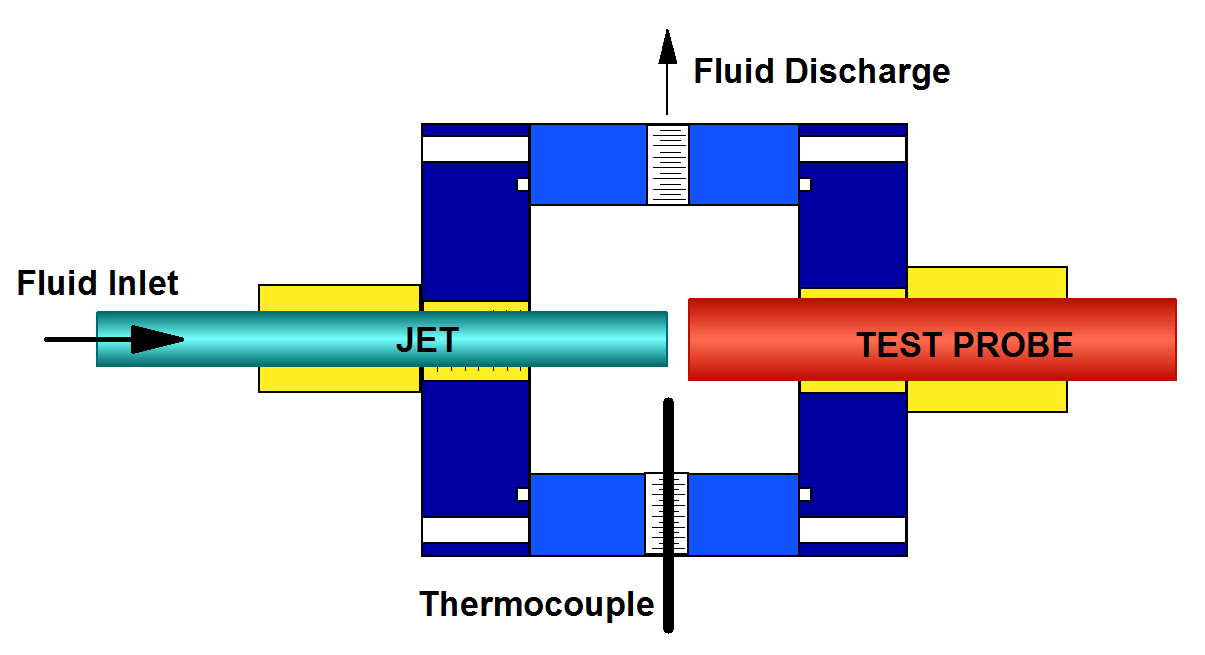

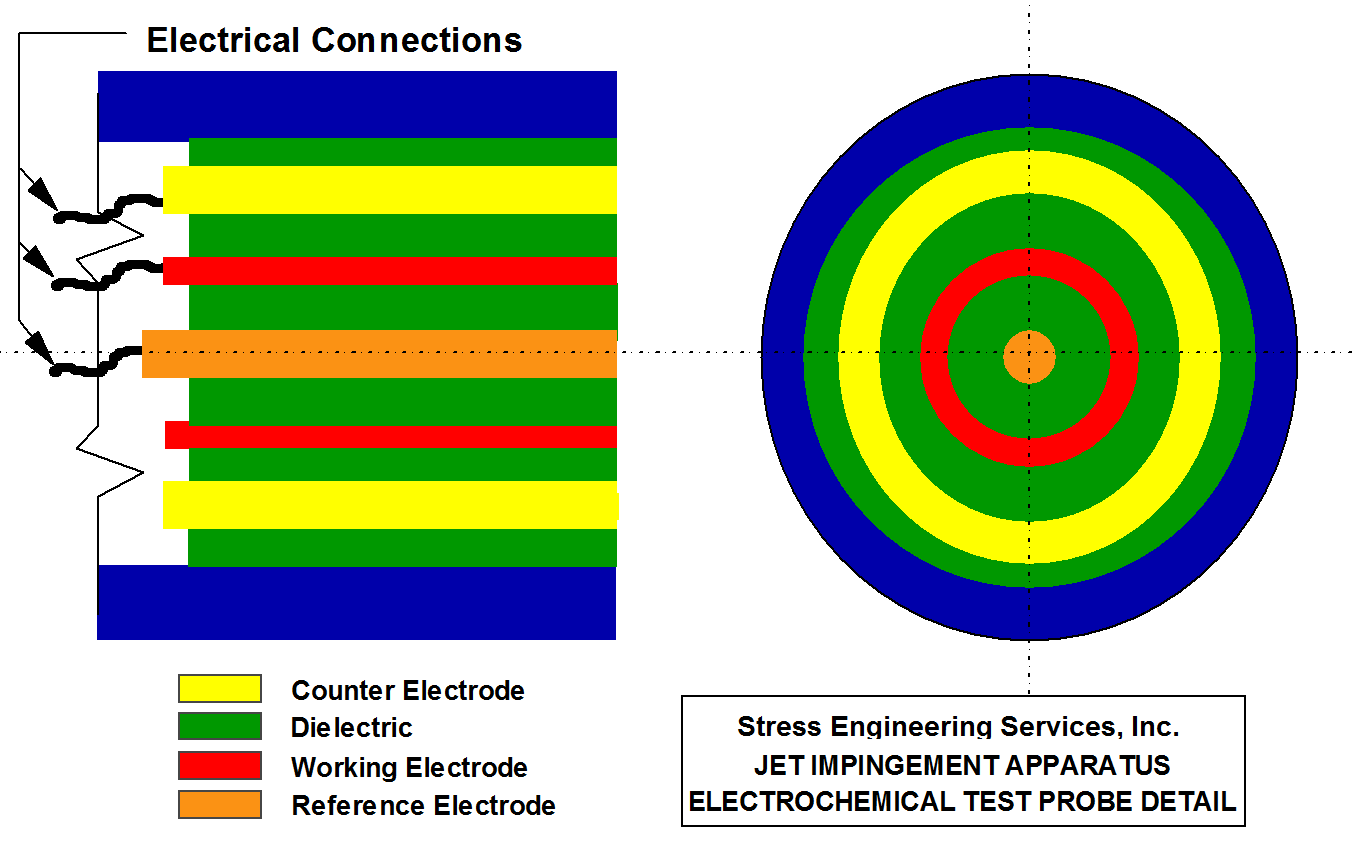

A schematic diagram of the jet impingement test cell, showing the relative position of the jet, test probe, and thermocouple monitoring the fluid temperature inside the cell, is shown in Figure 1. A schematic diagram of the test probe, containing the concentric ring electrodes that allows electrochemical corrosion measurements during the test, is shown in Figure 2. This figure shows the relative position of the reference, working and counter electrodes.

Why Jet Impingement Testing Works

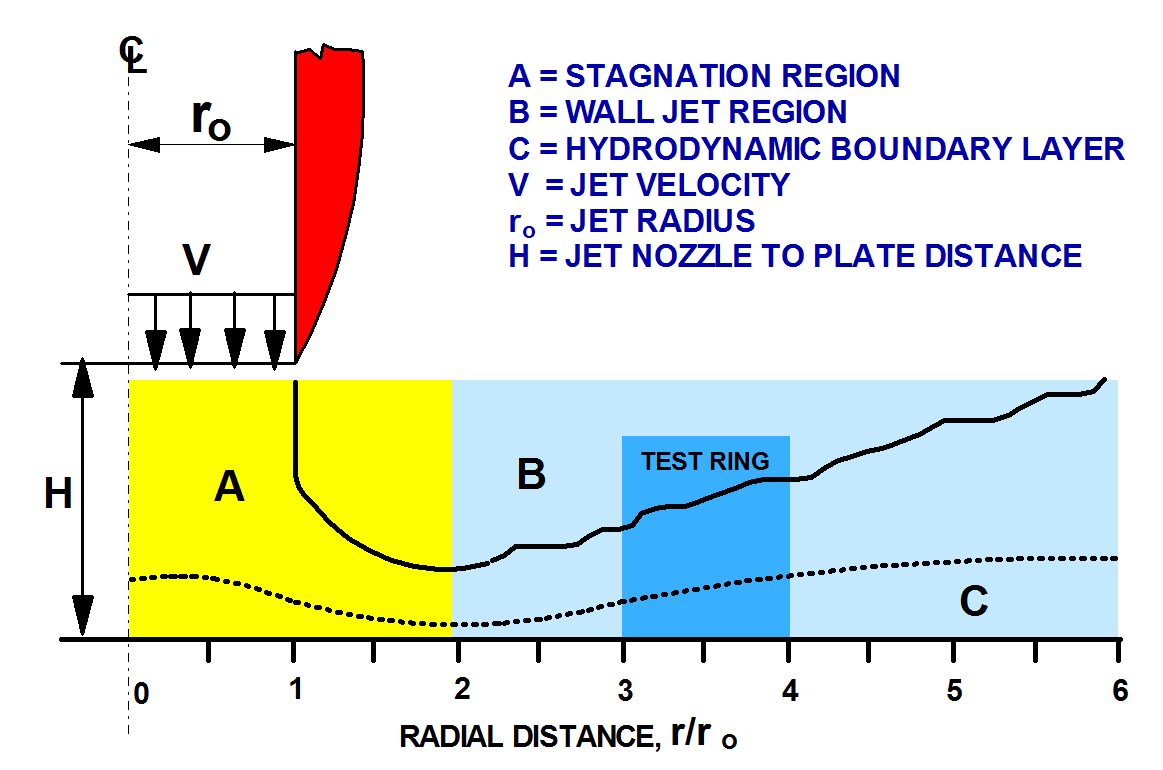

Jet impingement is useable for flow corrosion testing due to the hydrodynamic characteristics of a jet impinging on a flat plate, diagrammed in Figure 3. The fluid flow across the flat surface contains characteristic flow regions that are mathematically definable. Placing the working electrode of the test probe at a specific radial location in the jet allows measurement of the corrosion rate under those specific conditions.

The result, when the test ring is properly placed, is the ability to accurately and reproducibly measure corrosion rates under defined wall shear stress conditions. This wall shear stress can be experimentally measured through mass transfer correlation, or the wall shear stress can be mathematically calculated.

Correlation with Operating Systems

The wall shear stress on the test sample is the correlation factor used to relate the corrosion results to field operating systems. Wall shear stress measures the interaction of a flowing fluid with a solid surface. It can be related to any flow geometry, because it is a basic fluid/wall interaction phenomena and not a function of the specific flow geometry.

Data from any experiment that determines the wall shear stress acting on the test specimen can be effectively used for direct correlation to any flow geometry. Therefore, the wall shear stress calculated for an operating system…

Click here to download the complete article.

K. Daniel Efird, PE – Subject Matter Expert, Houston Office

K. Daniel Efird is a registered Professional Engineer in CA and NACE Corrosion Specialist. His professional background comprises 51 years of research, engineering and supervisory experience in corrosion, materials, and metallurgical engineering, including extensive experience as an expert witness. He holds BS degrees in Metallurgical Engineering and Chemical Engineering from North Carolina State University, and a MS degree in Materials Engineering from the University of Florida.

Leave a Comment

You must Register or Login to post a comment.