Lithium-Ion Battery Safety Testing

A key issue with lithium-ion battery (LIB) technology is thermal safety. With the proliferation of portable electronics and growth of the electric vehicle market, the demand for smaller and lighter batteries with greater capacity has never been higher. This increased demand and many high-profile incidents involving battery fires have led to increased scrutiny of battery handling and transportation. In addition, these incidents have fueled a significant amount of research in LIB safety.

Examples of battery safety incidents that have occurred recently include Dell laptop battery fires, hoverboard fires, grounding of Boeing 787 aircraft due to battery fires, and Samsung Galaxy Note 7 battery fires and recalls. These incidents are especially significant because the devices the batteries are installed in are designed for use in close proximity to people; therefore, the potential is great for causing bodily harm.

In all of these failures, the root cause can be attributed to either poor manufacturing quality control or poor design due to a lack of understanding of LIB thermal behavior in nominal and off-nominal conditions. These failures were caused by rapid heating leading to subsequent fire and/or vapor release, called thermal runaway. Due to the immediate risks associated with unexpected and uncontrolled fires, these incidents often lead to product recalls, which are very costly and can adversely impact the reputation of the system manufacturer.

Thermal Runaway in Lithium-Ion Batteries and Its Impact on Safety

The primary safety concern when using, handling, and transporting LIBs is thermal runaway. This is a phenomenon wherein a series of self-sustaining exothermic side-reactions lead to total failure of the cell and, in some cases, fire and/or explosion. Most LIBs have the potential to experience thermal runaway due to the chemical nature of current lithium-ion technology.

In comparison to the predecessor of LIBs (nickel-metal hydride batteries), li-ion cells contain higher electrical potential between the cathode and anode, often contain highly flammable organic electrolytes, and contain oxygen available for combustion from the lithium metal-oxide cathodes. These factors contribute to a greater potential for runaway reactions. Despite these risks, LIBs have displaced nickel metal-hydride systems in most applications due to the significantly higher energy density of LIBs.

While the exact mechanisms of and propensity to experience thermal runaway vary considerably between various LIB types and chemistries, the fundamentals of the process are the same. When a cell is operated outside of its design specification, thermal runaway can (and often will) occur. Examples of off-nominal conditions include:

- Thermal abuse including high or low temperatures

- Electrical abuse such as external short-circuits and over-charge/over-discharge

- Mechanical abuse including drop/impact, penetration, or vibration such that an internal short circuit is generated

However, thermal runaway can occur in LIBs even under normal operating conditions. Internal defects due to poor quality control during manufacturing or module assembly can lead to internal cell-level or module-level short circuits, which can generate excessive heat leading to a runaway condition and subsequent propagation. The occurrence and severity of thermal runaway in cells with defects is unpredictable, as seen with the well-publicized Dell laptop and Samsung Galaxy Note 7 fires.

Methods to help mitigate the risk of thermal runaway include cell-level electrical and thermal fuses (current interrupt devices and positive thermal coefficient devices), and module-level battery monitoring systems or protection circuits. Additionally, battery design plays a key role in thermal safety. Factors such as cell spacing, thermal management, and enclosure durability must be carefully selected with thermal behavior in mind. However, these types of safety systems often increase the weight, volume, and cost of the battery system and may be overlooked or eliminated in the drive to meet design targets.

LIB thermal behavior must also be considered when batteries are transported. The shipment of batteries on aircraft is now of special concern due to many recent safety incidents. Currently, many types of LIBs—both rechargeable and non-rechargeable—are barred from being transported in large quantities on passenger aircraft. Even on cargo aircraft, strict regulations are in place governing the shipping configuration (packaging and state-of-charge) permitted for various types and quantities of cells.

Regulation of the transportation of batteries is a developing area that is driven by experimental testing of batteries in various shipping configurations. Packaging must be carefully designed to minimize the risk of thermal runaway while in transit.

Using Safety Testing to Understand Thermal Runaway

Due to the complexity of the electrochemical/thermal system that is a LIB, the primary method to study their thermal behavior is to perform safety testing. Such testing can provide insight into critical questions shared by both battery engineers and end users alike, including:

- Which factors have the greatest influence on the probability and severity of a thermal runaway event?

- How can thermal runaway propagation be mitigated using safety-focused module design?

- What steps can be taken to improve the safety of LIBs during operation and transportation?

To help answer these questions and many others, Stress Engineering Services, Inc. (SES) is engaged in several battery safety testing programs including:

- Battery packaging characterization and safety assessment under off-nominal conditions

- Multicell thermal runaway propagation studies

- Cell-level assessment of thermal behavior at various states of charge (SOC)

- Charge retention studies at various states of charge

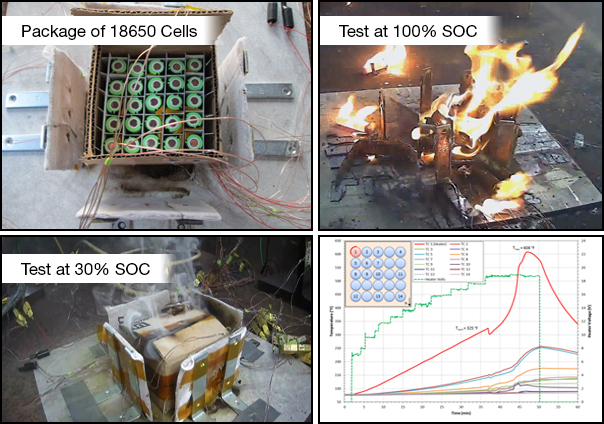

To better understand thermal runaway propagation in packages of LIBs during shipment, SES has tested packages of lithium-ion cells in a shipping arrangement. This work focused on the role that the packaging plays in thermal runaway propagation in the cells when subjected to external heating. Test variables studied by SES included external heater type, location, and heater protocol, arrangement of the cells in the packaging, electrical configuration, and the SOC of the cells during shipment. SES is helping regulators determine the best practices to improve safety during shipment and is developing methods to perform battery safety tests in a consistent, repeatable manner to verify shipping configurations.

In addition to testing of standard packaging, SES has also evaluated packaging designed to withstand thermal runaway. A specially designed container was tested that includes fire-suppressing material embedded in its walls. This material is activated when exposed to the fire emitted from LIBs during thermal runaway. This type of fire-resistant container could enable transportation of large batteries on passenger aircraft if regulatory bodies accept it as a viable solution.

It is generally known that battery SOC significantly influences the onset and severity of thermal runaway. Consequently, it is often required that cells be transported at a lower SOC—typically 30%. However, in SES’s propagation studies, we have observed very active thermal runaway events at SOCs as low as 3%, i.e., nearly fully discharged. To further study this relationship, SES is testing cells of different types, manufacturers, and capacities at several SOCs. These tests include charge retention, external short circuit, and external heating. The knowledge gained through these test programs will help shape transportation regulations in the future and improve safety.

Outlook

Despite the current safety concerns, LIBs are expected to become even more ubiquitous in the future. Breakthroughs in inherently safe lithium-ion chemistries are many years from being commercially available. In the meantime, it is essential that battery engineers understand the intricacies of thermal runaway and design for it proactively instead of reactively. SES will continue to assist our clients by increasing their understanding of issues related to battery thermal safety with comprehensive safety testing at the cell and module level.

Carlos F. Lopez, P.E. – Senior Associate, Houston Office

Carlos is a member of the Upstream Group at Stress Engineering Services and our resident battery consultant. He has extensive experience in battery testing and simulation in addition to experience in computational fluid dynamics and thermal analysis in a variety of applications. Carlos was also inducted into the Offshore Technology Conference (OTC) 2022 class of Emerging Leaders.

Leave a Comment

You must Register or Login to post a comment.