The Importance and Benefit of Full-Scale Testing for Additively Manufactured Parts

By: Patrick L. Boster, PE

Navigating the challenges of additive manufacturing requires more than innovative design; it demands rigorous testing to ensure operational viability. Full-scale testing bridges the gap between prototype and real-world application, providing a comprehensive evaluation of additively manufactured parts. This blog explores why full-scale testing is essential and how it addresses common challenges in preparing additively manufactured components for demanding environments.

The Crucial Role of Full-Scale Testing in Additive Manufacturing

Full-scale testing fundamentally verifies the endurance of 3D printed additively manufactured components under real-world conditions. Unlike testing that focuses solely on material properties or isolated features, full-scale evaluations scrutinize the component in its entirety—how it behaves under anticipated loading and pressures while being exposed to environmental conditions, such as temperature, corrosive media, and more—both as an isolated component and as integral part within its designated system.

This comprehensive approach is vital for components destined for industries that require a high level of reliability or where an additively manufactured component replaces a traditionally manufactured counterpart, ensuring that every aspect of the part’s performance meets or exceeds rigorous standards. At Stress Engineering Services, we take a proactive approach to testing—testing beyond the anticipated environmental conditions to ensure that a component performs optimally in its typical daily use.

Confronting Full-Scale Testing Challenges Head-On

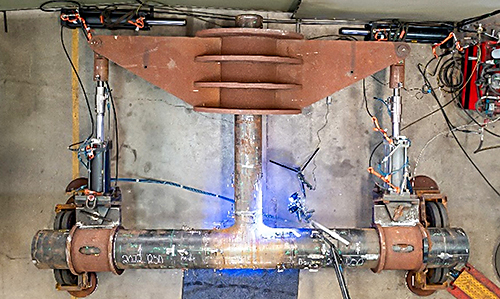

Regardless of a component’s manufacturing method, full-scale testing requires a multi-faceted approach that examines every operational aspect. For additively manufactured components that have not yet been proven, additional testing verifying early models, proof-of-concepts, and manufacturing methods provides assurance that they will perform at least as well as traditionally manufactured components.

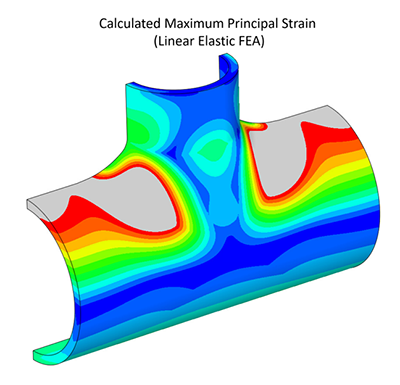

Confirming Model Accuracy

Doubts can arise about whether design models and preliminary design simulations, like Finite Element Analysis (FEA) models, accurately predict how an additively manufactured part will perform in its final installation, due to the sheer number of variables that affect component behavior. Design engineers program FEA models to simulate a component’s response to environmental circumstances, internal and external loads, thermal stressors, and more.

A controlled laboratory environment can help to validate the agreement between the engineering design and the component performance through a series of physical tests. These tests help to capture any nuance that may have been missed in simulation and help manufacturers and end users determine where adjustments are necessary for an optimal product.

Validating Additive Manufacturing Technologies and Processes

The essential variables of additive manufacturing processes must be treated like components of a balanced equation, ensuring the method of production yields results that are consistent and predictable for continuous service. By understanding the product’s operational environment and integrating it with the manufacturing process, you can guarantee that both the component and its construction method meet the highest standards of performance and reliability.

Testing to Component Specifications

Understanding a part’s operational context is crucial to effective and successful testing. Often, the choice to use additively manufactured components is dictated by a unique part geometry. A full-scale testing approach requires a deep dive into the component’s intended functionality, environment, and installation, with special consideration of unique fixturing. A complete understanding of the component’s functional and technical specifications allows for the customization of testing strategies to address its specific challenges and requirements.

Full-Scale Testing—Your Assurance in Additive Manufacturing Innovation

Full-scale testing is the linchpin in additive manufacturing component testing, assuring that parts not only match their design specifications but also function flawlessly under the strenuous conditions they will face once deployed. Stress Engineering Services’ comprehensive testing protocols are built on the foundation of this understanding, ensuring that every part tested can be trusted when it matters most. Our dedication to pushing the boundaries of what’s possible in additive manufacturing translates into parts that set the standard for quality, reliability, and performance in the field.

To witness the impact of comprehensive testing and our unique approach to additively manufactured parts validation, explore our case study with an additive manufacturing OEM on how a collaborative testing approach reduced an oil refinery’s maintenance downtime, from a worst-case scenario of several months, waiting on conventional materials, to a few weeks in recovery leveraging additive manufacturing technology and the Stress Engineering Services qualification process.

Patrick L. Boster, PE – Senior Vice President, Houston Office

Patrick is an accomplished leader, engineer, and expert in Additive Manufacturing, Product Qualifications and Welding Engineering. His professional experience and background includes over 40 years of materials and welding engineering and manufacturing support. This includes project management, product development, design review, nondestructive evaluation, and validation of manufacturing technology methods to successfully deliver equipment for even the most challenging offshore applications. He has also worked on prototype validation testing, equipment delivery and condition-based monitoring of offshore installations. Patrick has a Bachelor of Science Degree in Welding Engineering from The Ohio State University and is a registered professional engineer in the State of Texas.

Leave a Comment

You must Register or Login to post a comment.